Farmers bear more losses in summers and managing heat stress in poultry is not an easy task. For this issue, Think Grain Think Feed and Dr Jeetendra Verma connected with two leading personalities of the layer industry – Dr D. Chandrasekaran and Madan Mohan Maity to get some management tips and discuss other related topics. Read the below excerpts. One of the most immediate and obvious consequences of global warming is the increase in temperatures around the world. It is well-known fact that above 35 degrees is not favorable for poultry birds and creates a lot of problems like heat waves, bending of bars, more water intake, reduced feed intake, increased body temperature, etc. Farmers should focus on housing management, feed management, water management, and some general management.

Farmers bear more losses in summers and managing heat stress in poultry is not an easy task. For this issue, Think Grain Think Feed and Dr Jeetendra Verma connected with two leading personalities of the layer industry – Dr D. Chandrasekaran and Madan Mohan Maity to get some management tips and discuss other related topics. Read the below excerpts. One of the most immediate and obvious consequences of global warming is the increase in temperatures around the world. It is well-known fact that above 35 degrees is not favorable for poultry birds and creates a lot of problems like heat waves, bending of bars, more water intake, reduced feed intake, increased body temperature, etc. Farmers should focus on housing management, feed management, water management, and some general management.

Housing management tips

Open shed

- Poultry house should be in the East-West direction to manage proper sunlight

- Roof height should at least protect from direct sun rays

- Increase air moment inside the farm using the fans

- Roof should have good insulation and good support of foggers

- Avoid any obstruction of the tree and any other shades to protect the bars

- Shed width should not be more than 30-35 feet for hot climatic conditions with high humidity

Environmental shed

- Proper electrical voltage should be managed as in summertime electricity shortage is a common phenomenon, if possible, set up an electrical transformer in the shed to maintain the electrical voltage

Water management tips

- In normal weather conditions, feed intake to water consumption ratio is 1:2 but in

summer it is usually 1: 3

summer it is usually 1: 3 - Farmers should supply cool water directly from the pumps to drinking pipes between 10 AM to 4 PM which should not be held anywhere in between

- Farmers should provide sufficient electrolytes, especially vitamin A and C, in the early morning, it will help the birds

- Regularly flush out the hot water.

Feed management tips

- Feed should be given to the birds in a cooler part of the day early morning 3- 3:30 AM and in the late evening from 4:30-5.30PM

- Birds should not be fed in the middle part of the day

- Feed should be formulated as per the consumption, in normal conditions feed intake is 120 grams but in summer it is 90-95 grams, the feed formulation should be such that nutrition in 90 gm is the same as that of 120 grams

- Sodium bicarbonate is very helpful and it should be used in the feed as per the requirement in a hot climate.

General management tips

- Avoid any kind of activities like shifting, transportation, vaccination should be done in cooler parts of the day, if possible, it should be skipped

- Provide proper cross ventilation in shed

- Use a good quantity of foggers in the shed and it is better if one can use sprinklers above the shed

- Use white paint inside and outside as well

- Wet gunny bags should be used outside the shed, especially during mid-day (11.30 AM – 3.30 PM)

- Provide mid-night feeding (10.30 – 11.30 PM), during this time, water and feed intake would result in strong eggshell quality

Loss to layer farmers

In summers, even a managed farm can have losses of Rs 3-4 per month per bird and if it is not managed properly, the loss can be up to Rs 8-10 per month per bird.

Lower consumption is a common phenomenon

In summers, usually, there is 15% body weight loss in broilers and 8-13% egg production reduction can be observed in layers. On the other hand, consumption is also dropped by 15%. So, generally, farmers can’t lose the marker rate in summers due to reduced consumption, if it is managed well.

Summer management needs personal attention for keeping the birds comfortable. Initially, birds try to manage it naturally by reducing their feed intake, but continuous heat stress results in mortality. To overcome this, we should take care of water management and feed management.

Water management tips

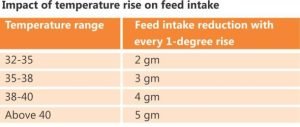

Water intake is usually 2-2.5 times of feed intake. But we find in an experiment that this ratio varies as per the temperature, at a peak temperature of above 40 degrees, it even increased up to 8 times of feed intake. So, water management is the prime factor to control heat stress. But water intake is reduced as the temperature increases, and the water pipeline gets heated, which needs to be flushed frequently. In summer, the feed to water intake ratio should be 1:4, if it is not so, farmers should take immediate action to correct it.

In summer, Metabolic Energy (ME) is reduced by 10% but reduced feed intake causes a 25% reduction in ME intake, and birds remain in a negative energy balance and they use the reserved energy from fat which causes Fatty Liver Syndrome when this continues the liver bursts causing the fatty liver hemorrhagic syndrome.

Feed management tips

Feed management tips

- Provide first feeding of 60 gm by 4 AM and stop by 9 AM. Once it is over, digestion and metabolism will take another 3 hours and by 12 o’clock, a decline in heat increment will start.

- Start the water management, macrolides should be added to water and it should be kept cool or at least in a drinkable condition.

- Feed the rest 40 gm by 4.30 or 5 PM, and the feeders must be empty by 8.30 PM.

- Add electrolytes in drinking water @ 1gm per liter by 9 AM and continue till 12 noon.

But if birds are fed after 10 PM, high egg-producing birds will keep on eating without bothering about heat stress and the mortality rate would be higher with such birds.

But if birds are fed after 10 PM, high egg-producing birds will keep on eating without bothering about heat stress and the mortality rate would be higher with such birds.

Disturbance in electrolyte metabolism is another major cause of heat stress, as the temperature rises, potassium and phosphorus are excreted and sodium level increases. In such conditions, birds try to manage by pumping out the sodium and controlling the potassium, and more energy is spent which comes out as heat. In the normal condition of metabolism, 30% of the maintenance energy is going into managing the electrolyte balance. In case of stress, it goes up to 40%. That means, in a total of 150–160 kilo calories given for maintaining per kg of metabolic weight, 15–20 extra kilo calories will come out as additional heat. This loss of 10% is due to electrolyte mismanagement. If one takes care of the above factors, mortality will definitely come down.

Other than this, sheds should have fans, especially in humid conditions, evaporative cooling is not possible when humidity is not below 65%, and disturbing the air is most important.

Use of foggers

The use of foggers is like a double-edged sword, farmers use the foggers to spread the water in the shed but they have to carefully notice the buildup humidity, if there is no wind movement, they should switch on the fans. Else, increased humidity will cause more mortality. In case they don’t have fans, other factors like more cold water should be considered.

Cold storage of eggs – A boon or a bane

Cold storage is used for a long period of storage, the eggs will be kept below 10 degrees and once it is out of the cold store sweating will occur, they should be sold within 24 hours else spoilage will be quick. But in AC room storage, the temperature is maintained at 25 degrees and it can be stored for 15 days. Cold storage is not recommended in the production belts but in the consumption belts.

Production difference in an environment controlled (EC) and open shed

Environment control sheds are common in commercial broiler farming, it is gaining acceptability in layer farming, but production difference will be 4-5% compared to open sheds. Managing layers in EC sheds in summer is not a big challenge but in winter if not properly managed fattening will be a problem. In peak summer, changing the light hours and dark hours will help, that is switching off the lights between 10 AM to 4 PM and switching on the light later, adjusting 6 hours can economize the power usage.

Improving maize quality in Bihar

Bihar is comparatively new to maize cultivation. Even 30 years ago, when Tamil Nadu started maize cultivation, the quality was low, but now the farmers are tuned to it and the quality has improved over the years. With the government intervention, maize production has grown from 30000 Tons to 700000 Tons. In the coming years, Bihar will be equally competitive. Fortunately, for the last 3 years, toxins have not been a problem with the Bihar crop. At present, producers (farmers) and consumers (poultry industry) don’t know each other, and if this can be changed, farmers would quickly adapt and produce as per industry standards.